Physical data

Filter sand is the most common filter media used in deep bed filtration systems. The reason is that it is the perfect filter media: inert, resistant to abrasion, free of impurities, available in a uniform grain-size distribution and relatively cheap.

Filter sand used in deep bed filters, such as continuous filters, may be abstracted from two sources: either from river beds or by mining. In continuous filters the river bed quartz sand is preferred as it is perfectly rounded due to the long-term natural erosion process. As the sand is continuously moving downwards in a continuous filter the rounded sand promotes homogeneous movement. This results in better filter performances. The river sand is dredged from the river basin and should be processed before it can be used for deep bed filtration. Processing consists of cleaning, drying and sieving of the raw material, in order to produce a product which is in accordance with a number of quality criteria.

The specific density of filter sand is 2.6 ton/m3, with a pore space or porosity of 40%. This is irrespective of the shape and grain size. This means that the apparent density of the filter media in a sand filter is equal to 1.6 ton/m3.

An important characteristic of filter sand is its hardness. The harder the material the better it will keep its shape in long-term filtration operations. The Mohs scale of mineral hardness is used to determine the filter media hardness. It is expressed in a qualitative ordinal scale from 1 to 10, characterizing scratch resistance of various minerals through the ability of harder material to scratch softer material.

Dutch river sand typically consists of 96% SiO2 and 2% Al2O3 and the loss of ignition should be low: < 0.5%. The sand is characterized by 7 on the Mohs hardness scale. To put this into perspective: gypsum is 2 Mohs, while diamond is 10 Mohs, the hardest material.

Figure 1. A rounded river sand grain used for filtration

Filter sand size and distribution

In a sand filter the grain size distribution is determined based on the application and the solids loadings. In drinking water applications grain sizes of 0.6 – 1.3 mm is typically used, while in waste water applications 1.2 – 2.0 mm is common.

If sand is supplied in a guaranteed grain size range then the upper and lower grain size limit is not rock solid. Ordering a grain size range of 1.2 – 2.0 mm, both the lower and upper limit allows for 10 weight% smaller and 10 weight% bigger grains.

Another important parameter, characterizing the filter sand, is the uniformity coefficient or UC. This is defined as a ratio and is calculated as the size opening that will just pass 60% of the sand (d60

value) divided by the size opening that will just pass 10% of the sand sample (d10 value). If the uniformity coefficient is below 1.5, it means that the sand particles are very similar in size.

For deep bed filtration the value of the uniformity coefficient should be between 1.3 and 1.5 to avoid stratification of the filter bed during backwashing. A lower value of the coefficient is possible, but this results in higher sieving costs and provides little additional advantage. In a continuous sand filter this stratification issue is not relevant as the sand washing procedure is quite different and the media is not expanded.

Filter sand in a continuous filter

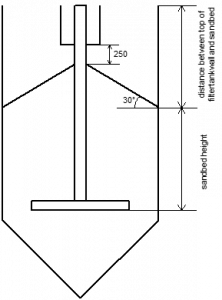

Once the filter tank is filled with sand (either using big bags or by bulk carrier, blowing in the sand) and the filter is operational, the sand bed looks like the cross section indicated. In the center of the filter the vertical airlift, at the top the washer assembly and at the lower side of the tank the distributor arms, feeding the filter. Then washed sand falls back onto the top of the sand bed in an angle of 30 degrees, equal to the natural slope. The effective sand bed height is the distance between the bottom of the feed distributor arms and the top of the sand bed, measured at the edge of the filter tank.

Figure 2. Sandbed height