In industry and electricity production cooling water systems are used on a large scale in order to remove excess process heat. A frequently used technique is the open circulating cooling water system, in which the process heat is discharged to the atmosphere by means of evaporation of a part of the cooling water to the air passing through the cooling tower. Some environmental aspects of this technique of excess process heat removal are:

- The withdrawal of water from natural resources;

- The evaporation of water to the atmosphere;

- The use of chemicals in order to prevent the cooling water system from corrosion, precipitation and microbial growth;

- The discharge of blow-down water, containing (in-) soluble components.

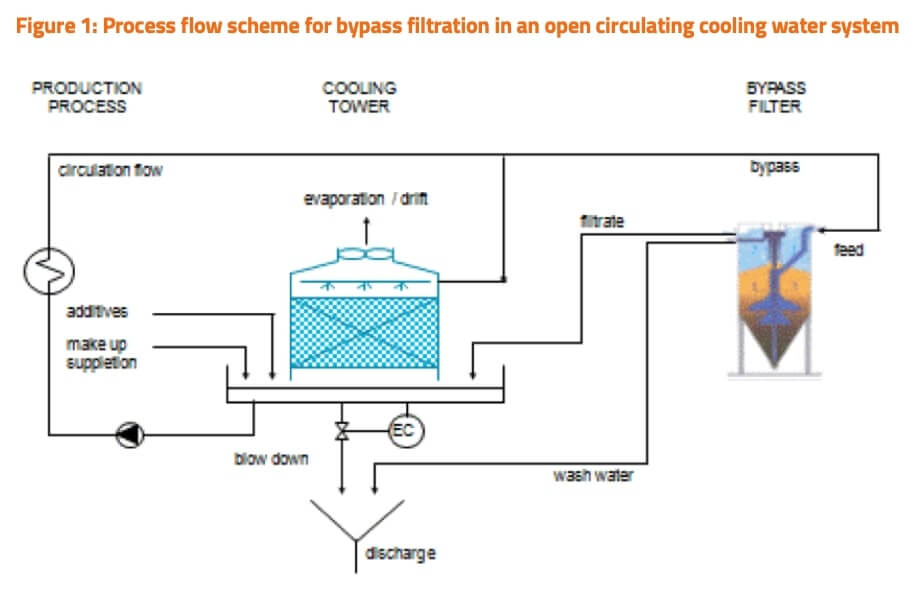

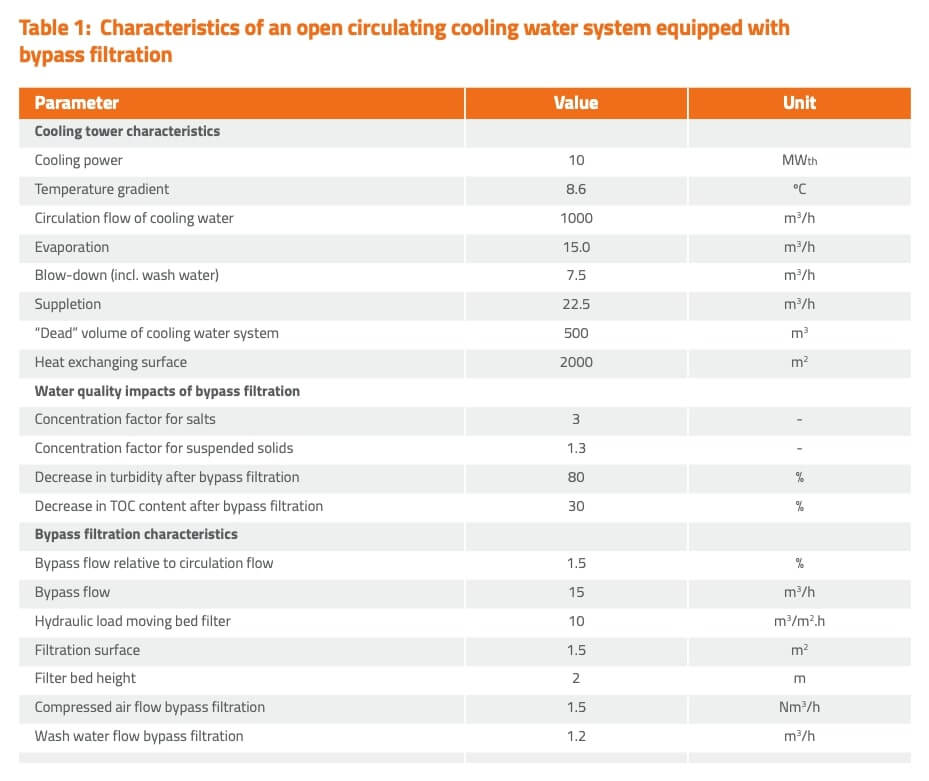

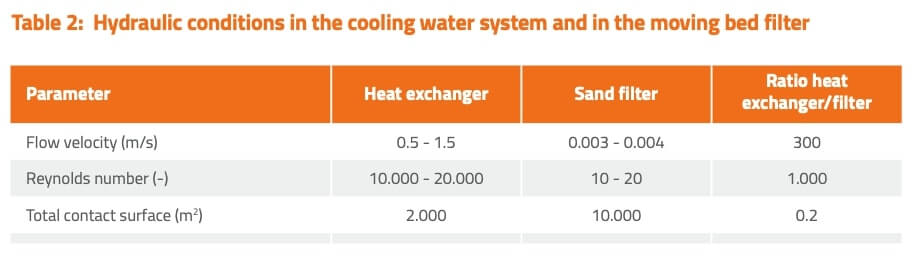

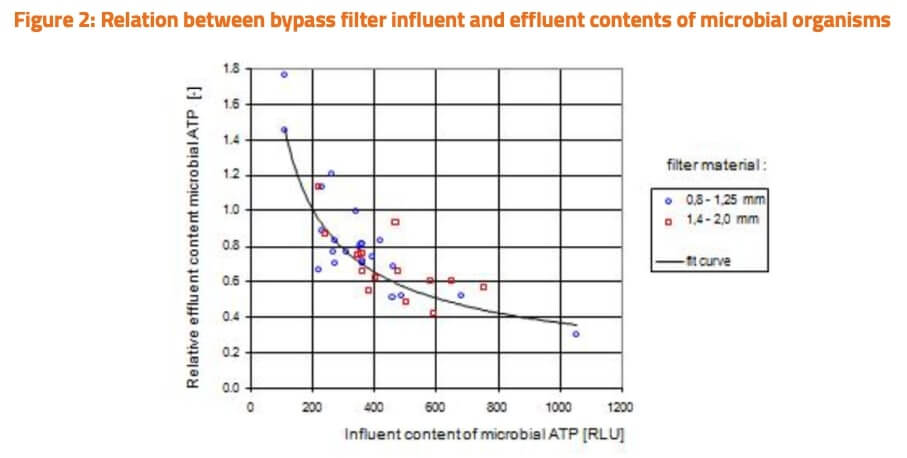

The concentration of pollutants in the cooling water system continuously increases because of partial evaporation, blow-in of mass via the airflow and because of microbial growth. These phenomena lead to contamination and corrosion in the cooling water system and require frequent maintenance efforts in order to minimize downtime of the production process and to prevent a decreasing heat transfer due to film formation on the surfaces of the heat exchanging equipment. The conditioning of the cooling water should also be focussed upon a minimization of the environmental burden (discharge of blow-down and supply of make-up water) and to a maximization of the reliability of the cooling water system. These two objectives are met at low financial costs by applying moving bed filtration on a bypass of the cooling water system. The system features are highlighted below.