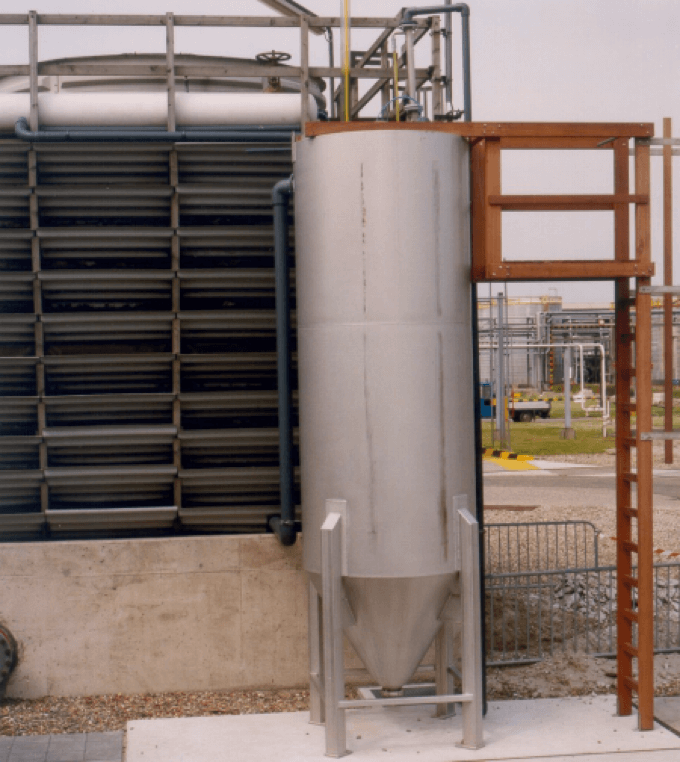

Cooling Water

Open circulating cooling water systems may be optimized by bypass filtration, for which moving bed filtration is a most efficient tool. The MBF treats a small part of the warm water flow, returning from the production processes. The filtrate is returned to the cooling water circuit, while the continuously released wash water is discharged to the blow-down pit. Bypass filtration is typically handling 1 – 10% of the recirculating flow in order to be effective. ROI is typically in the range of 6 – 12 months.

Cooling Water

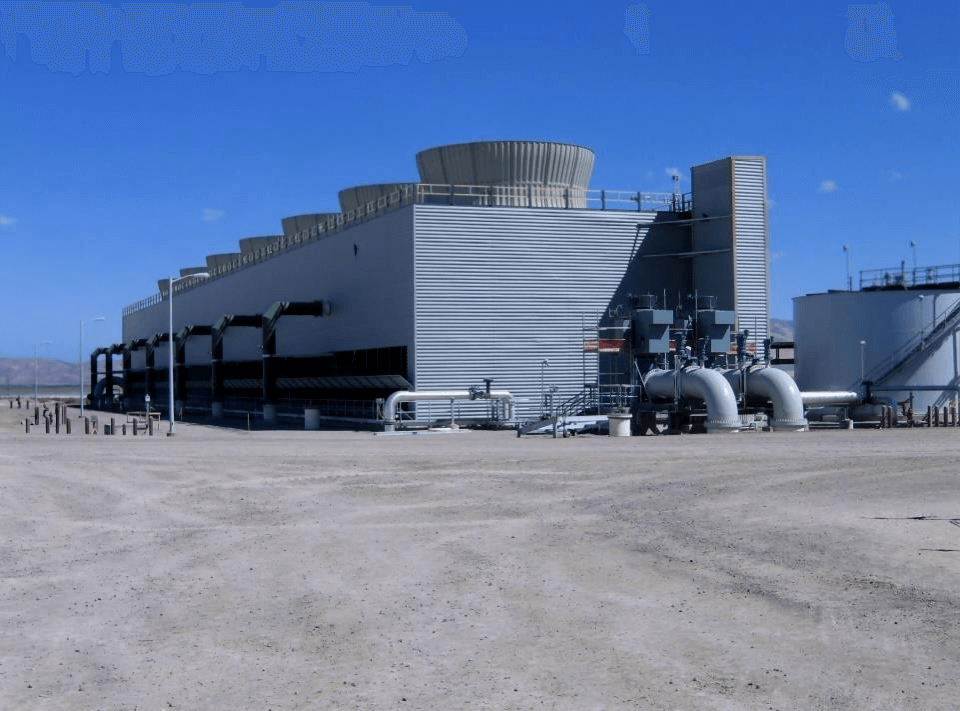

Improved Heat Transfer

For open circulating cooling water systems we developed a sustainable solution to improve heat transfer. By continuously cleaning a small portion of the circulating cooling water heat exchange is much more efficient.

Operational Savings

Operational savings are related to improved heat transfer (energy savings), less maintenance requirements, a reduction of conditioning chemicals. Typical return on investment is less than one year.

Asset Management

Cooling water systems are crucial assets in most industrial applications. Bypass filtration in open recirculating cooling water systems proved to be very effective in increasing lifetime expectancy of these assets.

How it works?

In an open circulating cooling water system a so called bypass filtration unit is fed with a small part of the warm water flow, returning from the production processes. Depending on the cooling water system characteristics a bypass filtration capacity of 1 –8% of the circulating flow is sufficient to achieve the goals: a better heat exchange, a reduction of chemicals consumption, less maintenance requirements and a higher uptime. In most cases a gravity feed to the filter is possible, with no extra energy requirements. The bypass filter is used for both solids removal and biological degradation of organic matter. The small wash water flow containing the retained solids is discharged to the blow-down pit. Generally it does not contribute to an increased blowdown.

Impact Modelling

Features

A simple add-on process

The offered solution is easy to implement. It directly contributes to the operational savings and more sustainable operations. The footprint is negligible in comparison with the cooling water system itself.

Return on investment < 1 year

Modelling impact, based on your plant characteristics, we will determine the return on investment. Generally this is less than one year for cooling water system capacities of 5 MW-thermal or higher.

Testimonials

We are happy to collaborate with our clients to meet their objectives. And we highly appreciate their feedback!

If I have to describe Brightwork in three words, I would characterize their capabilities by: reliable, innovative and service driven. I would certainly recommend others to work with them.

Jan Boonstra

Plant operator Wetterskip Fryslân WwTW Franeker

My impression of Brightwork is good, they are very skilful and knowledgeable.

Mattias Feldthusen

Director Process & Product Development

Nordic Water Products AB

Would you like some further reading?

Please feel free to download this whitepaper ‘’Bypass filtration in cooling water systems”. If you want your cooling water system characteristics to be run through our models, please contact us.