Continuous Sand Filtration

Moving bed (bio) filtration (MBF) is a mode of sand filtration based upon uninterrupted filter operation. Sand cleaning is continuous while the filter is in operation and hence a 24/7 availability of the process is guaranteed. The process features, advantages and applications of MBF are presented below. Three applications of MBF are discussed in more detail on the following subpages: biological (de)nitrification and wash waster treatment.

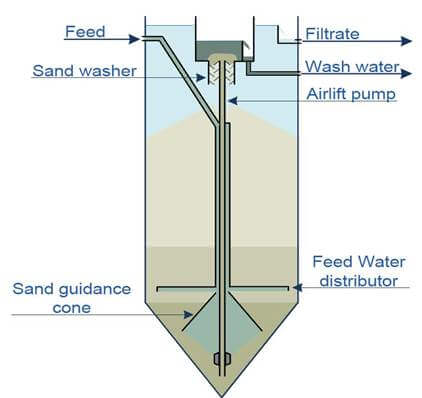

Mode of operation

Feed water is flowing upward through the filter bed. Filtrate is discharged at the top. Solids are retained and if applicable biomass converts organic components. Filter sand is continuously sucked into the lower end of the airlift and transported vertically towards the sand washer at the top of the filter. In order to achieve this only a small amount of compressed is required to run the airlift. Sand is washed continuously by using a small volume of filtrate. If required, process air is injected into the filter bed to create oxic operating conditions for the biomass to grow.

Advantages

– Continuous operation without any downtime for backwashing;

– No storage facilities required for wash water;

– No back wash pumps and compressors required;

– Applicable for simultaneous physical- chemical and biological treatment;

– Low maintenance requirements;

– Low operating and maintenance costs;

– No pretreatment required even at high TSS loads.

Process applications

– Biological nitrification;

– Biological de-nitrification;

– P-removal;

– Suspended solids removal.

– Wash water treatment

– Groundwater treatment

– Bypass filtration in open recirculating cooling water circuits

– Surface water treatment

How does it work?

Feed water is flowing upward through the filter bed. Filtrate is discharged at the top. Solids are retained and if applicable biomass converts organic components. Filter sand is continuously sucked into the lower end of the airlift and transported vertically towards the sand washer at the top of the filter. In order to achieve this only a small amount of compressed is required to run the airlift. Sand is washed continuously by using a small volume of filtrate.

If required, process air is injected into the filter bed to create oxic operating conditions for the biomass to grow.