Surface water treatment

Surface water treatment for process or drinking water production requires an analysis of the feed water quality and water quality variations. With high levels of organics (expressed in chlorophyl-a) and/or high levels of inorganic solids tilted plate settling is the right choice.

A well balanced mixing of chemicals, coagulation and flocculation upstream of the tilted plate separation in function of actual flows, temperature, solids load is important to achieve good settling results.

Is direct continuous filtration thé solution to treat surface water?

The straight answer is: no, not always, but sometimes it might be! If it is suitable it is a wonderfully simple process set-up: after feed strainers you apply a continuous sand filter with in inline feed dosing of coagulants. The filter acts as a flocculator and a floc separator, resulting in a stable high quality filtrate.

But how do we know when this is feasible? We tried to offer you some guidance.

For surface water treatment the solids loading to the filter is based upon variable feed water quality, as the river water quality may vary considerably with respect to turbidity, colour and suspended solids. The continuous filtration is capable of handling high solids loadings and may therefore be used as a single process step avoiding the need for pre-treatment by settling or dissolved air flotation. In order to efficiently remove colloidal matter an in line dosing of flocculants is normally projected.

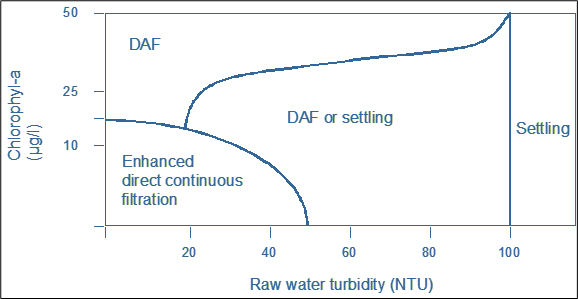

However this is not always applicable, so you should be careful. We have drafted a process selection diagram, related to feed turbidity and feed organic material (expressed in chlorophyll-a). You can see there is a particular sweet spot for enhanced direct continuous filtration. If your feed surface water quality is within this operating window, you might consider this process. The result is a very simple, reliable and robust treatment process, with a small (carbon) footprint.

Surface water process selection diagram

The table below illustrates typical results of a surface water treatment scheme, based upon direct continuous filtration. The plant has a design capacity of 160 m3/h; a flocculant is dosed in-line, using alum. Typical dosages are in the range of 2-6 mg/l Al. Together with our Sand-Cycle monitoring and control technology we are able to consistently meet the filtrate criteria.

Table: Surface water treatment plant with direct continuous filtration – Water quality data

| Parameter | Raw Water | Filtrate | Criteria |

| Turbidity (NTU) | 20-25 | 0.1-0.2 | < 0.5 |

| TSS (mg/l) | 1-50 | 0,5 | <1 |

| Temperature (oC) | 1-25 | ||

| Transmission (%) | 30-50 | > 96 | |

| Fe (mg/l) | < 0.05 | ||

| Al (mg/l) | 0.05-0.60 | < 0.1 | < 0.1 |

| Mn (mg/l) | < 0.05 |

If you are interested in this topic, please have a look in our library, containing relevant white papers: for this topic we recommend the white paper with the title: “‘Treatment of RO concentrate with continuous sand filters” for more information”.