Technologies

We use our technologies to compose solutions to help you solve your water issues. Our portfolio consists of a wide range of technologies, developed for a variety of applications in waste water treatment, surface water treatment, cooling water conditioning, ground water treatment and wash water handling.

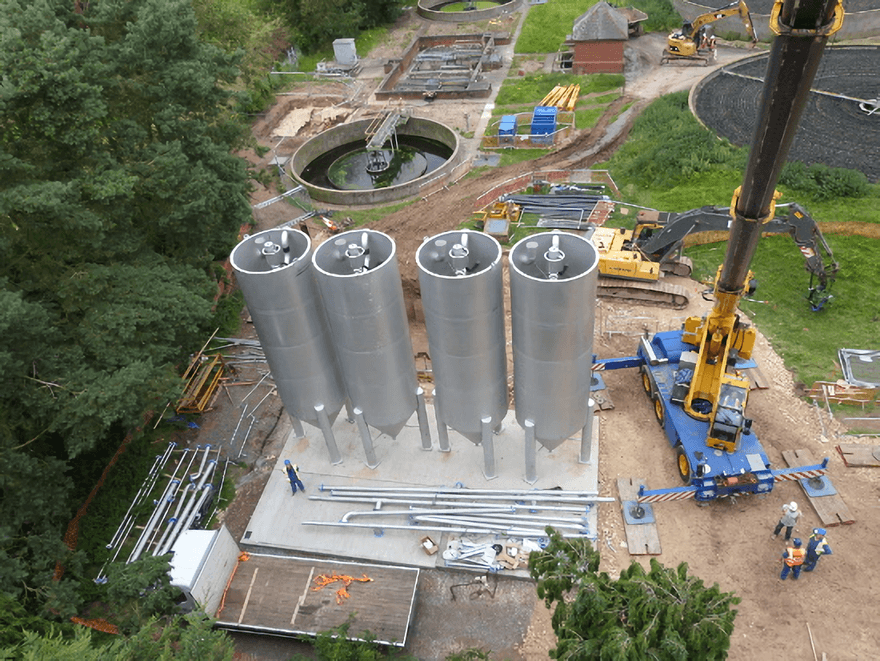

Continuous Sand Filtration

Continuous moving bed (bio-)filters are used to remove suspended solids, phosphorus, nitrogen, BOD/COD, heavy metals and/or aromatic carbons. We have applications in waste water treatment, surface water treatment, cooling water bypass filtration, ground water and wash water handling. The process has proven to be vary reliable in a wide operating window.Tilted Plate Separation

Tilted plate lamella settlers are used for various settling applications, both primary and secondary settling, creating a large settling area at a small footprint. The technology may be combined with upfront controlled coagulation and flocculation to achieve a high settling performance.

Sand-Cycle monitoring and control

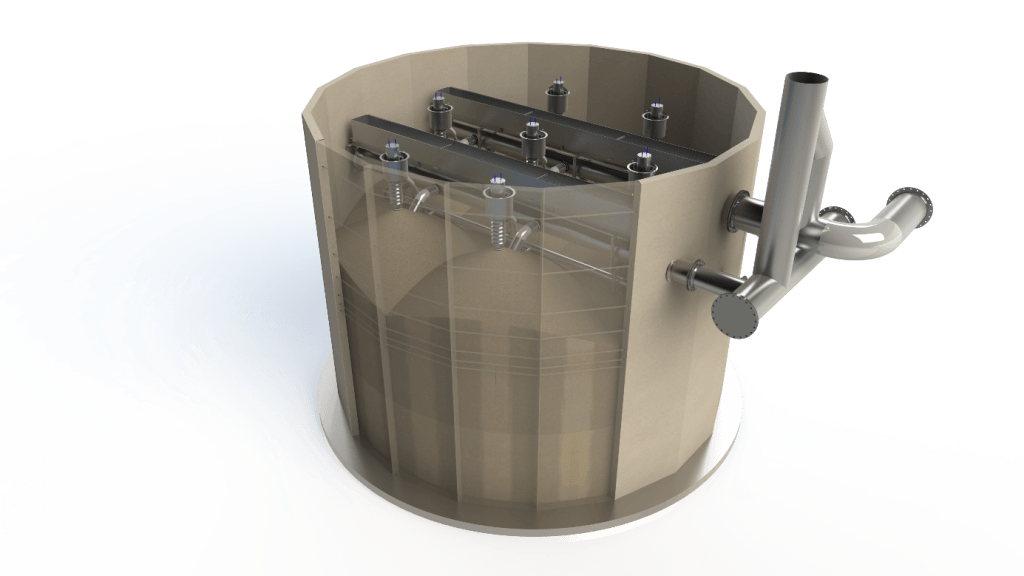

Sand-Cycle has been developed as a powerful remote monitoring and control tool to improve performance of continuous sand filters, to reduce operational costs ánd to make life easier in the day-to-day operations. Sand-Cycle uses RFID tags, which are added to the sand filter bed, acting as a proxy for the sand movement in the filter.Ecoblue filter

A modular circular sand filter design, based on the Verdygo principles results in a continuous media filter reactor with a capacity of 400 - 600 m3/h each. Both sand and granular activated carbon may be applied.

Pile cloth filtration

Pile cloth filters are combining the advantages of disc filters and the deep bed filtration mechanism. Solids are trapped into the 3D cloth which promotes high efficiencies. The technology is used to remove solids, phosphorus and powdered activated carbon.Disc and drum filtration

Disc and drum filters are suitable to remove solids in both surface water and waste water applications. The applied mesh widths of the discs may be choosen such that the right removal efficiencies are achieved. The low head loss requirements of the technology makes it easy to implement in an existing treatment plant.

Adsorption processes

Both powdered and granular activated carbon is used in combination with the moving bed filtration technology to remove micropollutants.Coagulation

A good coagulation process is crucial for creating flocs which may be separated by either settling, flotation, sand, cloth or disc filtration. A coagulation design using a static, hydraulic or mechanical mixing, based upon the appropriate energy input will achieve the right conditions.

Flocculation

A good flocculation process is essential for building strong flocs which will be easy to separate by either settling, flotation, sand, cloth or disc filtration. A flocculation design requires a combination of an appropriate hydraulic retention time and energy input. Both hydraulic and mechanical flocculators are applied to accomodate this process.Mixing

Both static mixers, mechanical mixers and hydraulic mxing devices are used to mix coagulants with the liquid to be treated. An appropriate design takes into consideration the variations in flows and loads and guarantees the energy input to be sufficient for instanteneous mixing.

Granular activated Carbon filtration

GAC filtration is widely applied to remove a variety components from water by adsorption onto the activated carbon. The process is applied in both static GAC filters and continuous moving bed GAC filters. The design is based upon a proper understanding of the required empty bed contact time, bed volumes and filtration rates. Also biologically enhanced GAC filtration is applied to increase the time io regenerate the GAC.Cascade Aeration

In ground water treatment schemes appropriate aeration of the raw water is required to efficiently remove iron and manganese and to be able to biologically convert ammonia-nitrogen into nitrate-nitrogen. Cascade aerators are used to implement an easy to maintain and efficient process component.

Aqua Assist and BioReactAD

Both Aqua Assist and BioReacAD are products to enhance the biology in waste water treatment, both in the water line and in the anaerobic digesters. The product consists of granular silica based material enriched with selected microbial material. Lower waste activated sludge volumes, higher conversions in the AD plant with consequential higher biogas production are achieved.

More information can be found in the white paper:

WWTP reaches > 25% waste activated sludge reduction with AquaAssist