Coagulation & Flocculation

Coagulation is crucial for creating flocs which may be separated by either settling, flotation, sand, cloth or disc filtration. Flocculation is essential for building strong flocs for efficient separation by either settling, flotation, sand, cloth or disc filtration.

Coagulation & Flocculation

Spot on energy input

Bringing in the required energy input for both coagulation and flocculation is crucial for building flocs which are strong enough for efficient separation. The applicable GT-values depend on the floc characteristics and determine the final separation result. Both mechanical and hydraulic coagulation and flocculation designs are offered.

Excellent floc formation

Floc formation is a delicate balance between the solids characteristics, the dosing of chemicals, pH conditions, retention time, energy input and flocculation configurations.

If all conditions are met and a proper coagulation and flocculation design is made, the downstream separation process will perform.

High performance

Whether you are applying dissolved air flotation (DAF), lamella settling (TPS) or media filtration, the upstream conditioning is vital for a stable and high separation performance. We are taking into consideration all relevant process parameters to achieve the best possible results. If needed bench or pilot scale trials may be executed.

How it works

Coagulation and flocculation occur in successive steps intended to overcome the forces stabilising the suspended solids in the water or waste water to be treated. The coagulation process is a rapid process destabilizing the forces which are avoiding particles to collide. After destabilizing it allows particle collision. Small flocs are then growing into bigger flocs by using flocculants dosed into flocculation zones, using adequate energy input for agitation. These bigger flocs may now be removed by settling, reducing the turbidity of the water. Several crucial design parameters for this process should be carefully considered. The selection of coagulants (e.g. primary salts, such as iron and aluminium salts) and flocculants (kationic, anionic). The retention time, the flocculation configuration (plug flow, number of compartments), the (decreasing) energy input and pH conditions.

Applications

Coagulation and flocculation is applied in both water and waste water treatment. In water treatment a common application is the removal of turbidity and colour from surface water sources. Depending on the turbidity level, colour figures and/or organics both a two-step coagulation – flocculation – settling – sand filtration is applied and a direct filtration with in line coagulation.

In waste water treatment coagulants are often used to remove both (colloidal) solids and phosphorus. Depending on the coagulant used the optimal pH conditions may differ depending on the major objective.

Configurations

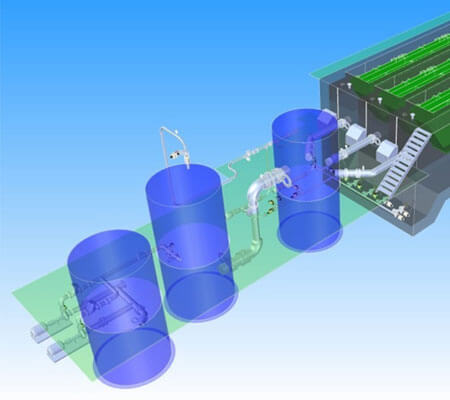

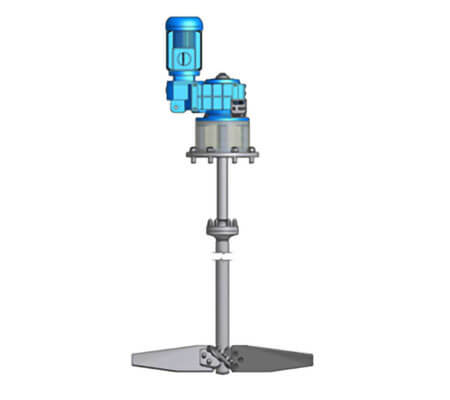

Mechanical

The most commonly applied coagulation and flocculation set-up is based upon mechanical mixing and agitation. Design is governed by the energy input, expressed in GT values. A series of flocculation tanks with agitators running at decreasing energy input allows for increasing floc growth.

Hydraulic

With constant process flows, a hydraulic mixing and flocculation may be considered. Not using mechanical equipment makes the set-up more simple. Mixing may now be executed using a cascade arrangement. Flocculation is achieved by implementing submerged compartments separated by perforated baffles.

Would you like some further reading?

Please feel free to download this whitepaper ‘’Surface water treatment selection diagram”