Llanberis WwTW

2019 -2021

Client: DCWW, UK

Keywords: Wastewater, tertiary treatment, continuous sand filter, solids removal, Fe, P: waste water treatment, continuous sand filter, phosphorus removal, upgrade, optimization, coagulation, flocculation

Project description

EU water utilities are facing tightening permit consents for phosphorus to protect our surface water quality. Existing tertiary technologies at municipal waste water plants should achieve consistent and reliable results. The Llanberis WwTW (DCWW) in the UK is equipped with a tertiary continuous sand filter plant to particularly meet 0.5 ppm total phosphorus consent levels.

Two BluePro filters, each with a capacity of 10 l/s, were initially installed in 2012 – 2015 to meet the total phosphorus levels by so-called adsorptive P-removal. However, the plant proved to underperform and hence a refurbishment plan was executed, with the objective to inspect the filters, remedy anomalies and to establish a stable and consistent phosphorus removal by coagulation, flocculation and filtration.

BluePro filters at WwTW Llanberis, prior to refurbishment

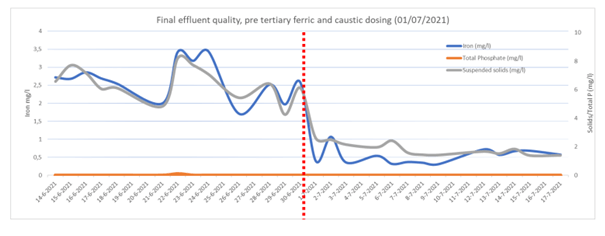

Impact of refurbishment on filter performance for removal of solids and total phosphorus (vertical red dotted line indicates the start of operations after refurbishments).

Solution

After an intensive site survey and setting up a diagnosis of the required remedial works a plan of action was composed. A variety of actions have been taken: the exchange of filter internals and filter sand, the construction of a dedicated inline mixing for coagulants, the bypass of an external flocculation zone, the implementation of the Sand-Cycle monitoring and a dedicated control of the feed flow and chemical dosage.

After the full implementation of the tertiary coagulant dosing, the primary and secondary coagulant dosing has been interrupted. This led to a considerable decrease of the overall chemical consumption: the ferric dosing decreased from 8 l/h (fixed flow) to 3 – 4 l/h (variable flow), the caustic dosing reduced from 7 l/h to 5 l/h. As a result the chemical sludge volume reduced and stable and low residual Fe levels were found in the final effluent.

Testimonials

We are happy to collaborate with our clients to meet their objectives.

And we highly appreciate their feedback!

“Through collaborative working with Brightwork a better understanding has been gained into continuous moving bed sand filtration systems. Using the novel Sand Cycle technology, developed by Brightwork from the Netherlands, has given rise to better understand the relationship between sand bed movement and filtration efficiencies. Paving the way to higher removal efficiencies, towards optimized real-time load-based operations.”

Gareth Medley

Conway Engineering

Contact Brightwork

We are always open for queries and suggestions. Please do contact us if you have a particular question, remark or request.