In een continu zandfilter passeert het water het filterbed in opwaartse richting. De stroming van water door een poreus medium resulteert in een hydraulische drukval. Deze drukval noemen we de filterbedweerstand. De werkelijke waarde van deze filterbedweerstand wordt gemeten door het verschil in opvoerhoogte in de toevoerleiding naar het filter en het filtraatniveau in het filter af te lezen, zoals aangegeven in de figuur. Hetzij met behulp van een drukmeter, hetzij door eenvoudigweg het waterniveau in de ontluchtingsleiding boven in het filter te meten.

Weerstand van het filterbed

De weerstand van het filterbed, Hfilterbedkan worden onderverdeeld in twee componenten:

Hfilterbed = H0 + Hdepositie (1)

H0 wordt aangeduid als de weerstand tegen schoon bed; dit is de hydraulische weerstand ten gevolge van de waterstroming van een schoon filterbed, zonder afzettingen in de poriënruimte.

De tweede component, Hdepositiestaat voor de extra filterbedweerstand ten gevolge van afzettingen in de poriënruimte van het filtermedium.

In blog #5 hebben we laten zien hoe de schoonbedweerstand wordt berekend. In deze blog gaan we de relevantie beschrijven van de tweede component Hdepositie in de vergelijking van de filterbedweerstand op de filterprestaties.

In het water aanwezige onzuiverheden worden in de poriën van het filterbed afgezet. Door deze afzettingen worden de poriën nauwer, wat leidt tot extra weerstand van het filterbed.

Een belangrijke factor die van invloed is op de filtratie-efficiëntie is de vullingsgraad van de poriën. Een hogere vullingsgraad van de poriën in het filterbed vormt een extra barrière voor vaste stoffen die het filter binnenkomen. Dit leidt in het algemeen tot een betere filtraatkwaliteit. Ook bekend als "vuilvangend vuil".

Om de filterefficiëntie te verbeteren is dus een bepaalde hoeveelheid afzettingen nodig, die kan worden bereikt door de zandcirculatiesnelheid te verlagen. Hoe lager de toegepaste zandcirculatiesnelheid, hoe hoger de hoeveelheid afzettingen, hoe hoger het extra verlies aan filterbedhoogte, hoe hoger de filterefficiëntie.

Dit geldt totdat het maximaal toepasbare drukverlies is bereikt. Zoals aangegeven in een van onze eerdere blogs is dit maximale drukverlies gedefinieerd als 2/3 maal de bedhoogte.

Het wijzigen van de zandcirculatie bij continue filtratie gebeurt door het aanpassen van de luchtstroom naar de luchtlift. De zandcyclusbewaking en -regeling van continue filters is ontwikkeld om juist deze gunstige omstandigheden te verkrijgen. Zandcirculatiesnelheden waarmee het filtersysteem binnen een drukverliesbereik kan werken om aan de beste prestatievoorwaarden te voldoen.

Illustratie van veldgegevens

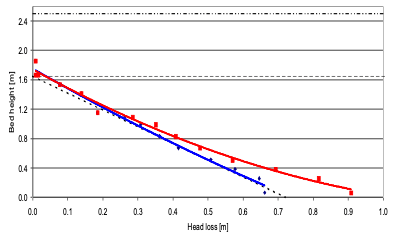

In een continu filter zal het merendeel van de depositie zich aan de aanvoerzijde van het filterbed bevinden, net boven het distributiesysteem van de filtervoeding. Dit wordt geïllustreerd in figuur 1, waarin het XY-diagram van het stijghoogteverlies en hoogte van het filterbed. Het filter (met een bedhoogte van 1,8 m) werkt met een filtratiesnelheid van 14 m/h bij een watertemperatuur van 10 graden C. De toegepaste zandkorrelgrootteverdeling is 0,8 - 1,25 mm. Het zuivere bedhoogteverlies bedraagt 0,40 meter per meter bedhoogte.

Twee verschillende procesomstandigheden worden geïllustreerd: de blauwe lijn vertegenwoordigt een hoge zandcirculatiesnelheid (12 mm/min), geen afzetting en dus alleen hydraulisch drukverlies. De rode lijn toont een lage zandcirculatiesnelheid (2 mm/min), met als gevolg de opbouw van afzettingen in het onderste filterbed, waardoor extra drukverlies door afzettingen ontstaat.

Een vergelijking van het verschil in filterprestatie voor troebelheidsverwijdering voor deze twee bedrijfsomstandigheden geeft de relevantie aan: de gemiddelde prestatie neemt toe met 15 - 40%. Indien het continue filter bovendien als biofilter wordt gebruikt (b.v. voor stikstofverwijdering) draagt deze optimalisatie ertoe bij dat meer biomassa in het filter wordt vastgehouden, waardoor de biologische omzetting wordt bevorderd.

Samenvatting

Opvoerhoogteverlies is een belangrijke procesparameter bij continue filtratie. Het bestaat uit twee componenten: het hydraulische drukverlies en het drukverlies door afzettingen in het filterbed. De aard van het continue filtratieproces maakt het mogelijk om het drukverlies door afzettingen in het filterbed actief te regelen. De luchttoevoer naar de luchtlift regelt dit drukverlies actief. Dit zal over het algemeen leiden tot hogere filterprestaties.

Figuur 1 - Opvoerhoogte versus bedhoogte voor twee procesomstandigheden met verschillende zandcirculatiesnelheden in een continu zandfilter